Feature

-

Automatic counting function, effectively control filling quantity

Import single-chip microcomputer control, high efficiency, low power consumption

LCD display, touch screen is very easy to operate

Filling Accuracy is high, precise volume

Wide Voltage range

Working performance is stable and can be used for long time

Self-suck function, don't need to pour

-

The pump can stand for PH value within 5-8

-

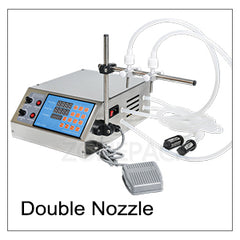

Anti-dripping design

-

Reasonable design, made of stainless steel, meet GMP requirement

-

Speed Parameter Range: 1-9, Filling Time Range: 0.01-99.99s, Interval time Range: 0.01-99.99s

-

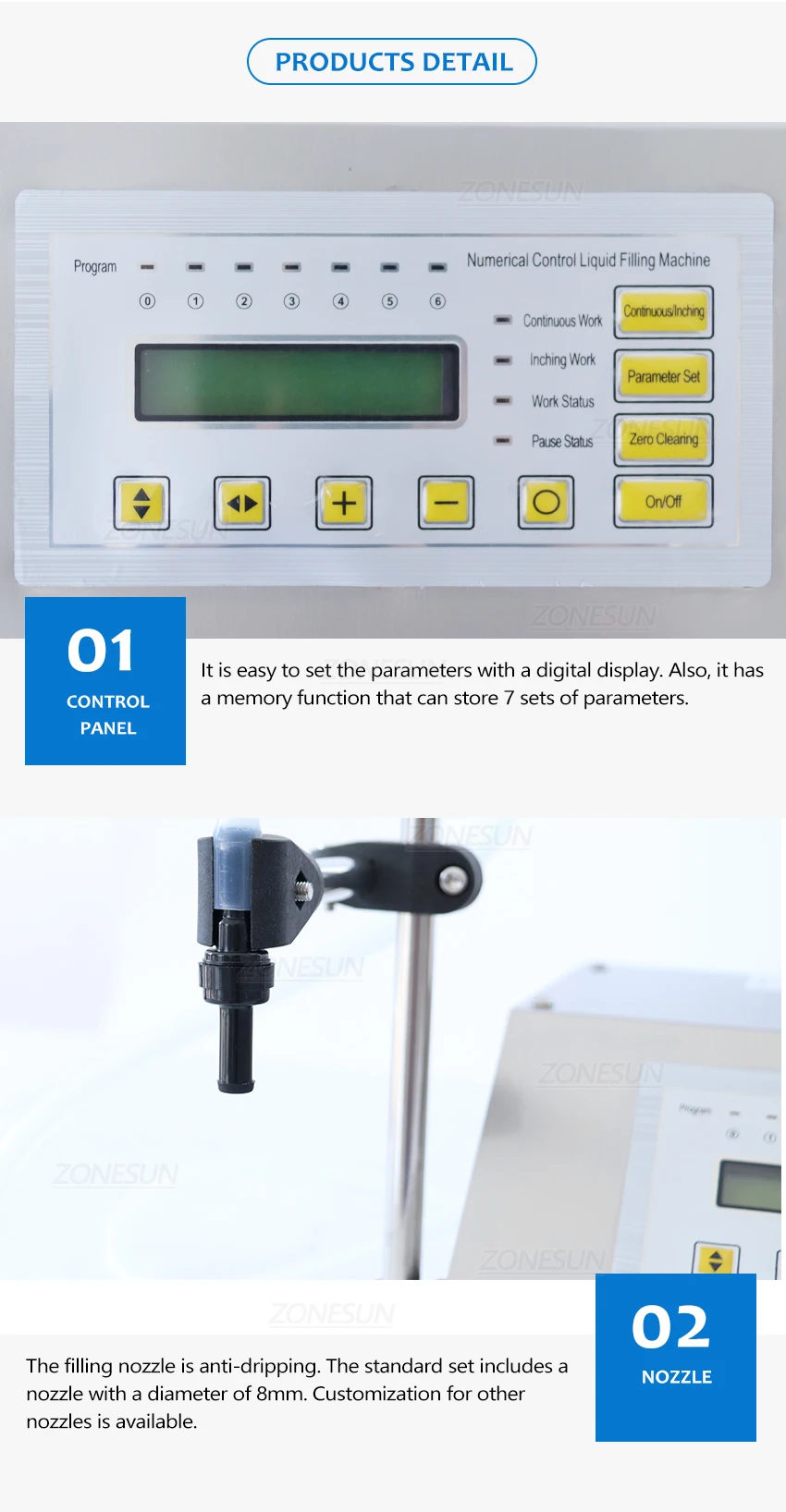

Save up to 6 sets of parameters for different-sized bottles and can choose from easily

-

Widely used in chemistry, food, beverage, oil, and cosmetics, etc.

-

Suitable for filling low-viscous liquid without pellets

The pump can stand oil, heat, weak acid, weak alkali, abrasion and chemical products

-

Integrates the advantage of self-suck pump and chemical pump

Self suck, heat protect, stable working and continuous idle or load operate for long time

Parameter:

Voltage:AC110V-140V/180V-260V

Power:30W

Max Flow Rate:3.2L/min

Max Suck Distance:2m

Repeat Error:<0.5%

Package Dimension:400×380×200(mm)

Filling Volume Range:5ml-3500ml

Anti-dripping Function:Available

Memory Function without Electricity:Available

Machine Size:350 X 270 X 150(mm)

Diameter of Filling Nozzle:Φ 8mm

Suitable Soft Tube:17#(interior diameter: 6.4mm, thickness: 1.6mm, max pressure0.24Mp)

Note: Different liquid needs to choose different material of tube. The tube provided by us is silicone tube.

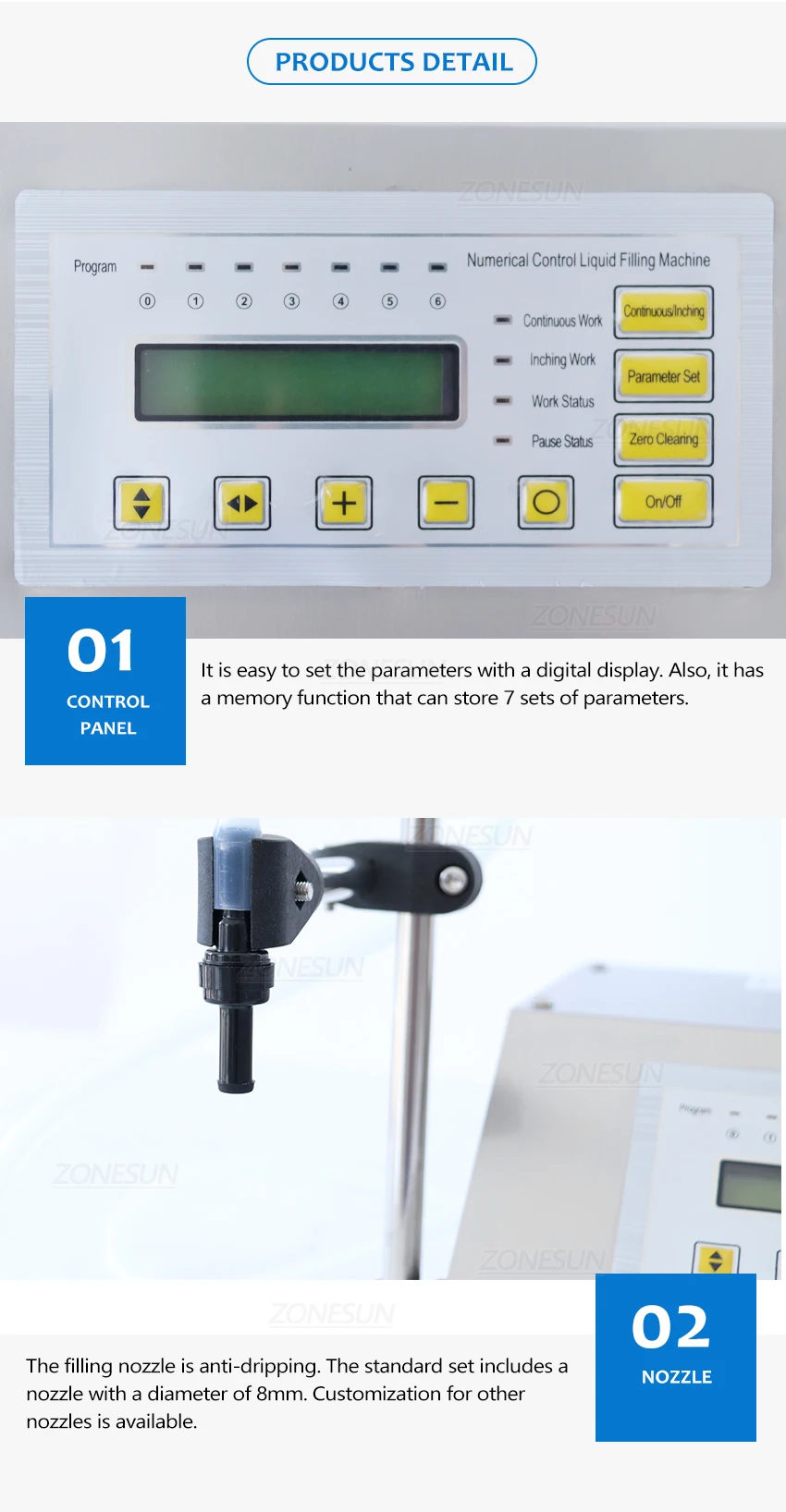

Description

Updated Model GFK-160 5ML-3500ML Digital Control Pump Liquid Filling Machine

This Updated GFK series numerical control liquid filling machine uses micro-computer to control the mini-pump on filling time and the rotation rate of electric motor so that the machine can fill the liquid fluently and at high accuracy. Separated with the electric motor,the pump is made of a variety of anti-corrosion imported material. There is no mechanical metal part or abrasion inside the pump.

This numerical control liquid filling machine is compact and portable. The casing uses stainless steel so it is durable and easy to clean. The machine has a self-prime pump that can suck in the liquid from your container and then output via the nozzle. It can be used to fill many different types of clear thin liquid,including water, olive oil, fuel, drinks, vinegar, milk etc.

Liquid suitable: low viscous liquid like water, wine, solutions etc.

Liquid unsuitable: very thick liquid (sauce,detergent etc), or liquid containing small particles.

The tubes are made of silicone gel and the pump head is made of PVC plastic material so it can endure mild acid/alkaline solutions. The machine has a control front panel and digital display. You can easily enter your parameters by pressing the buttons on the control panel and the parameters will show in the LCD screen. The filling volume can be controlled via the filling time and speed parameters which give you much flexibility.

Installation

Take the plastic filling nozzle out and install it in the feeding tube. (Notice the triangle head connects the discharge tube). Take out the filling-head stand and install it on the left of the machines. Put the filling head in the clip and tighten it by socket wrench.

Connect the pedal switch with machine, and put the tube with filter below the liquid level inside the storage rank. The position of tank should be lower than the machine. Start to test the machine after all is ready.

Attention

We will test all of the filling machine before send out , so it's normal that the machine pump and tube with water inside when you receive it.

We upgrade this filling machine,the dimension is smaller than before one.Functions are same as before machine.Please notice that the USA customer and RU customer may receive the old filling machine since we ship them randomly.

Characteristics

1.Imported single-chip control,high efficiency,low power consumption

2.Automatic counting,control the filling quantity effectively.

3.LCD display,touch screen panel is easy to operate.

4.Filling Accuracy is high,precise volume.

5.Wide voltage use range.

6.Product working performance is stable,long use life.

7.Self-suck function,don't need to pour.

8.Pump can stand the acid and alkali.

9.Anti-dripping design

10.Reasonable construction design,stanless steel shelf,meed GMP requirement.