Rotary Pump Paste Filling and Capping Integrated Machine: An Efficient Filling Solution

The rotary pump paste filling and capping integrated machine is a multifunctional device that achieves bottle placement, filling, cap placement, capping, and bottle ejection through its unique workflow. This machine utilizes a rotary disc working platform and is particularly suitable for filling creams, gels, sauces, and other paste-like products. This article will introduce the working principle and advantages of this machine, as well as its application value in the paste filling industry.

Workflow

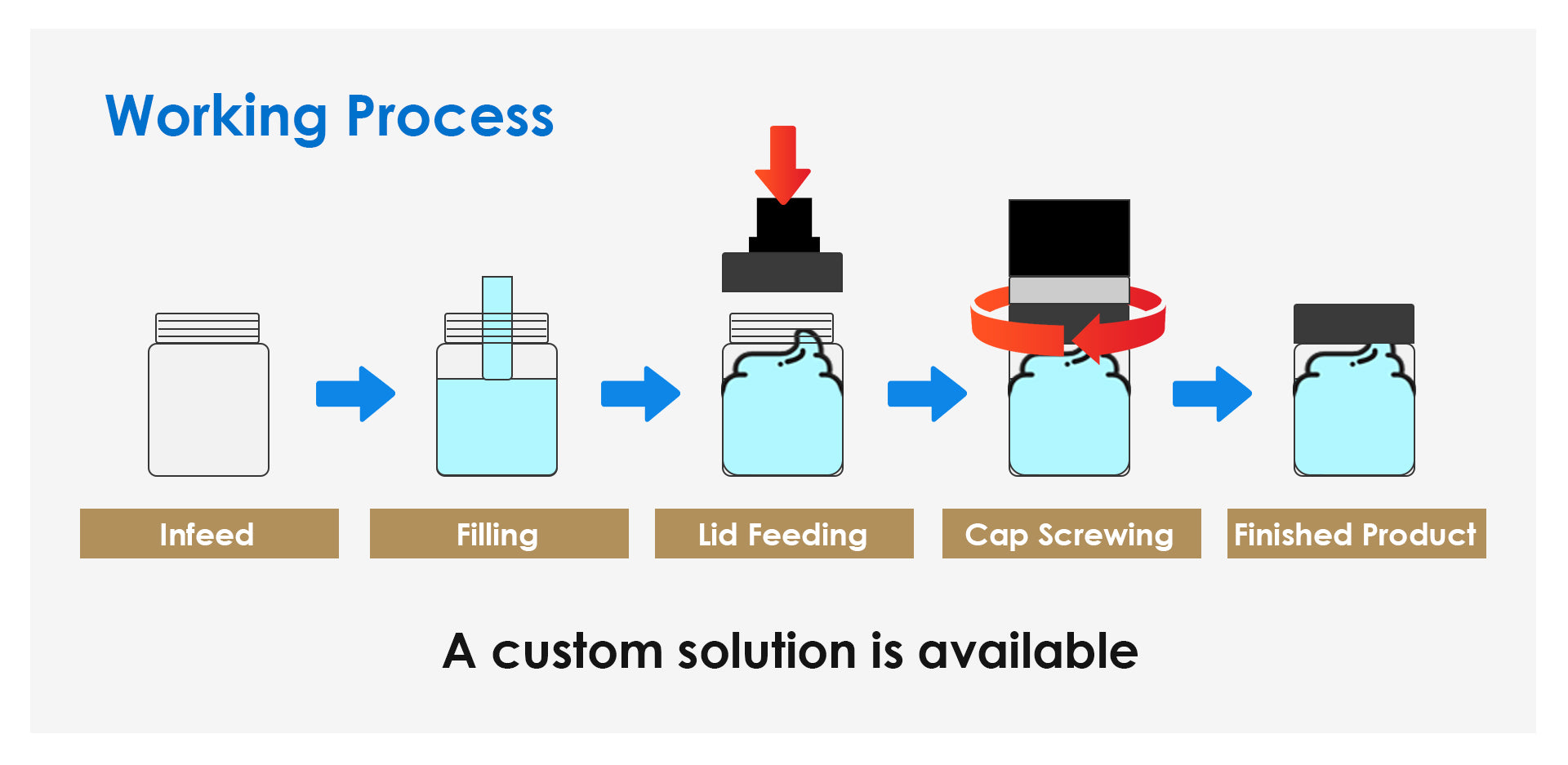

The rotary pump paste filling and capping integrated machine follows a simple and efficient workflow, including the following main steps:

-

Bottle Placement: The operator places empty bottles on the rotary disc working platform, which automatically rotates and transfers the bottles to the next workstation.

-

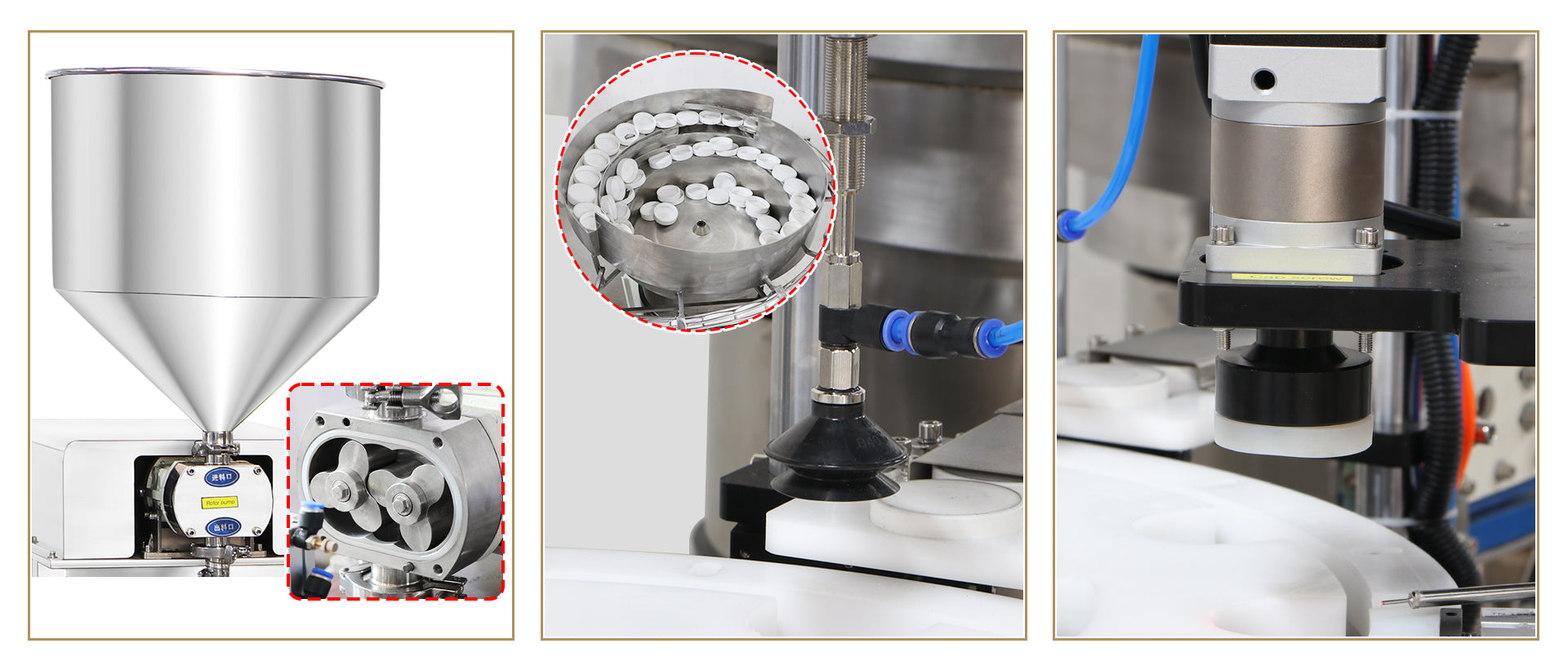

Filling: At the filling workstation, the rotary pump starts its operation. The rotary pump consists of a rotating rotor and a fixed housing, which draws the paste through rotation and delivers it into the bottles. Due to the special design of the rotary pump, it can handle various viscosities of paste, such as creams, gels, and sauces.

-

Cap Placement: At the cap placement workstation, the machine automatically retrieves suitable caps and places them on the filled bottles.

-

Capping: Next, at the capping workstation, the caps are securely tightened to ensure proper sealing of the bottles.

Advantages and Applications

The rotary pump paste filling and capping integrated machine offers numerous advantages and wide-ranging application value in the paste filling industry:

- Efficient Production: This machine adopts an automated workflow, enabling quick and accurate completion of a large volume of filling and capping tasks, thereby improving production efficiency.

- Precise Filling: The rotary pump technology ensures precise control and stability during the filling process, avoiding waste and leakage, and ensuring product quality.

- Suitable for Various Paste Products: Due to the characteristics of the rotary pump, this machine is suitable for filling various viscosities of paste products, including creams, gels, sauces, etc.

- Flexibility and Adjustability: The machine features adjustable parameters and filling capacities, allowing for flexible adjustments based on product requirements to meet different specifications and demands.

The rotary pump paste filling and capping integrated machine serves as an efficient solution for paste filling and has found wide applications in the cosmetics, pharmaceutical, and food industries. Its fast, precise, and reliable performance provides manufacturers with a convenient and high-quality production process, thereby enhancing product competitiveness in the market.

The rotary pump paste filling and capping integrated machine serves as an efficient solution for paste filling and has found wide applications in the cosmetics, pharmaceutical, and food industries. Its fast, precise, and reliable performance provides manufacturers with a convenient and high-quality production process, thereby enhancing product competitiveness in the market.

ZONESUN TECHNOLOGY LIMITED specialized in the filling machine ,capping machine,labeling machine,sealing machine,wrapping machine,production line and other packaging machinery , ZONESUN with many years of experience and technical expertise. Our team consists of a group of highly skilled and experienced professionals who can provide customers with high-quality packaging machinery products and professional after-sales service. We can provide customized packaging machinery solutions according to the specific needs and requirements of our customers, in order to meet their different production needs. From machine design, manufacturing, to after-sales service, we always put customer needs at the center and constantly improve the quality of our products and services, in order to provide customers with a better product and service experience. If you have any packaging machinery needs, please feel free to contact us at any time. We will be dedicated to serving you!

https://www.zonesunpack.com

E-mail:info@zonesunpack.com

Whatsapp:+0086 18924567106