quality assurance

We pride ourselves on delivering products of the highest quality. With a rigorous quality assurance process in place, our products meet and exceed industry standards.

2%OFF NOW & CODE:ZONESUN1 ($299-$10)

Chinese Company:Guangdong Shanghang Technology Co., Ltd.

Add: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

Company name:MAYLERESCAPE LIMITED

Company Address: UNIT# 2052 275 NEW NORTH ROAD LONDON UNITED KINGDOM N1 7AA

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one for our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Contact Support

We know some customers may need the product urgently and hope they can place the order as soon as possible.In this situation,we offer e-mail and online chat support to help our customers to know more thing about our products and service.For contact support:

ZONESUN TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

1st of south 2nd Shuikou road Jinsha Town Nanhai distric Foshan, 528223 Guangdong, China

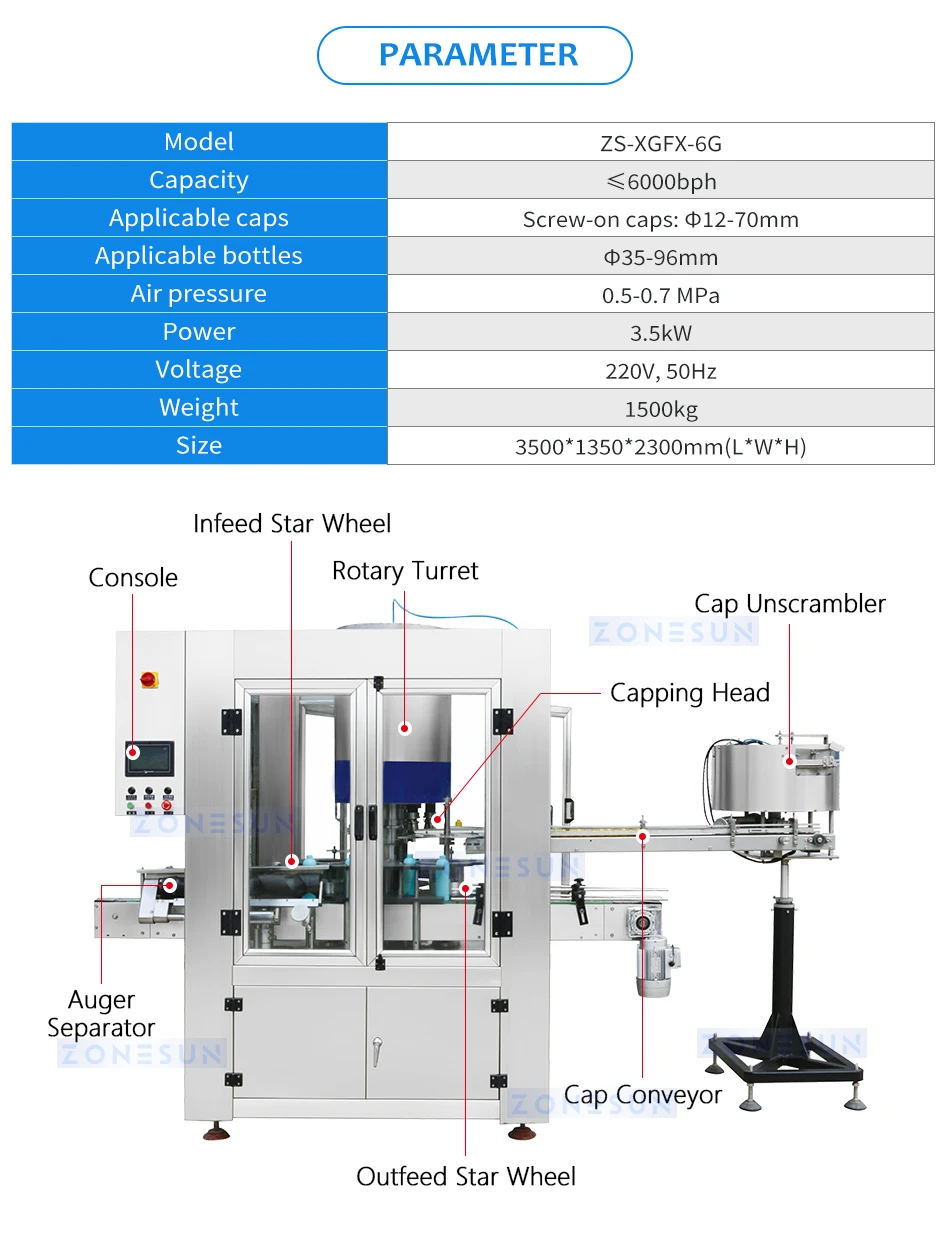

DESCRIPTION

The Rotary Screw-on Capping Machine has a capacity to cap up to 6000 bottles per hour. The auger separator is responsible for separating the bottles and feeding them onto the infeed star wheel. The infeed star wheel moves the bottles in a single file towards the rotary turret. The rotary turret is the core of the machine, holding the bottles in place while the capping heads rotate to screw the caps onto the bottles. Once capped, the bottles move on to the outfeed star wheel, which moves them out of the machine for further processing. Above the outfeed star wheel, there is a star wheel for feeding caps transported from an outside cap unscrambler. Whatever your packaging needs are, you can rely on ZONSUN.

PARAMETER

|

Model |

ZS-XGFX-6G |

|

Capacity |

≤6000bph |

|

Applicable caps |

Screw-on caps: Φ12-70mm |

|

Applicable bottles |

Φ35-96mm |

|

Air pressure |

0.5-0.7 MPa |

|

Power |

3.5kW |

|

Voltage |

220V, 50Hz |

|

Weight |

1500kg |

|

Size |

3500*1350*2300mm(L*W*H) |

AUGER SEPARATOR

The auger separator is located at the beginning of the machine's production line and is responsible for separating the bottles from each other and feeding them onto the infeed star wheel. It consists of a motor-driven auger screw that rotates inside a tube.

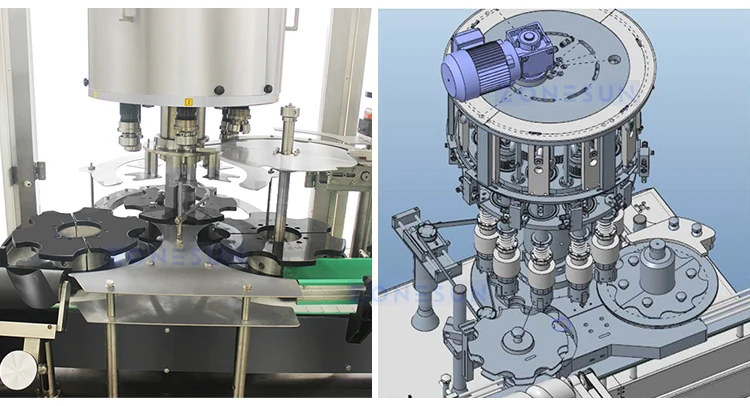

CAPPING

The rotary turret is the core of the machine and is responsible for holding the bottles in place while the capping heads screw the caps onto them. The capping heads are fitted with gripping mechanisms that hold onto the caps and rotate them as they screw onto the bottles. The turret is designed to move the bottles through the capping heads quickly and accurately, ensuring that each bottle is capped securely and with the same level of tightness.

CAP FEEDING

The cap unscrambler is responsible for sorting and orienting the caps and feeding them onto the cap conveyor. Once the caps are on the conveyor, they move towards the star wheel, which is designed to hold and support the caps in an upright position. The star wheel moves the caps towards the capping heads as they pass through the rotary turret.

COMPONENTS

It uses components from well-known brands, as these components are often reliable and of high quality. These components can help ensure that the machine operates smoothly and efficiently, with minimal downtime.

We pride ourselves on delivering products of the highest quality. With a rigorous quality assurance process in place, our products meet and exceed industry standards.

© 2024, ZONESUN Machinery Powered by Shopify