With the increasing demand for powdered products in the market, powder filling machines have become vital automated equipment that provides efficient, hygienic, and flexible solutions for manufacturing companies. This article will introduce a state-of-the-art powder filling machine equipped with a vacuum feeding device, mixing unit, touch screen control panel, high-precision spiral filling, and easy-to-adjust filling heads. It also highlights the inclusion of a weighing device that ensures product weight accuracy and production quality. This machine can be customized according to customer requirements and is suitable for filling powders, protein powders, milk powders, corn starch, and more.

https://www.zonesunpack.com/products/zonesun-zs-mb500fp-powder-filling-machine-production-line

Advantages of Vacuum Feeding Device and Closed System

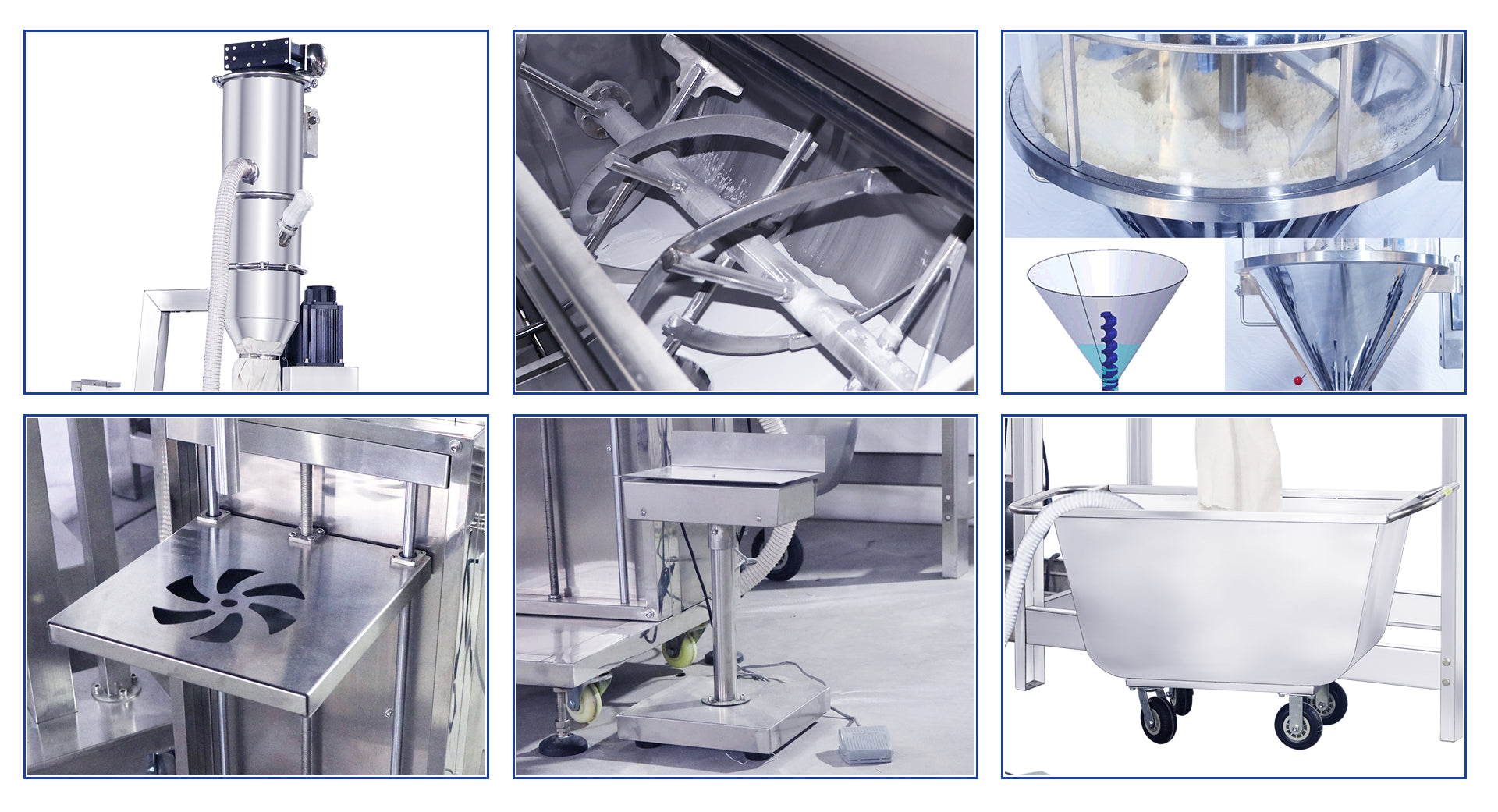

Traditional powder filling machines are susceptible to gas contamination and material leakage during the feeding process, compromising hygiene and safety. In contrast, this powder filling machine utilizes a vacuum feeding unit to transport materials within a sealed system, effectively preventing contamination and leakage issues. The vacuum feeding device not only enhances product hygiene and safety but also ensures process stability and consistency.

Versatile Mixing Unit for Increased Product Diversity

The mixing unit is a key feature of this powder filling machine. It thoroughly blends different types of powders, ensuring uniform product quality. The adjustable mixing intensity and time allow users to flexibly customize the mixing process according to product requirements. This multifunctional design provides businesses with greater production flexibility and product diversity.

Convenient Operation with Touch Screen Control Panel

Equipped with an intuitive touch screen control panel, this powder filling machine enables users to easily adjust various operational parameters such as filling speed, volume, and mixing time. The user-friendly interface streamlines the operation process, reducing the need for manual intervention and enhancing production efficiency and accuracy.

The powder filling machine employs high-precision spiral filling technology, ensuring accurate product weight and filling volume. Additionally, the design of the filling heads allows for convenient adjustment of the filling capacity to accommodate various product specifications and volumes. This precise and flexible filling capability makes the machine excel in filling various powders, protein powders, milk powders, corn starch, and other products.

Customizable Applications and Production Quality Assurance

This powder filling machine can be customized to meet customer requirements, accommodating products with different shapes, capacities, and packaging needs. Furthermore, it is equipped with a weighing device that enables real-time product weight detection, ensuring production quality compliance. The customizable applications and weight detection feature make this filling machine an ideal choice for a wide range of powdered products.

ZONESUN TECHNOLOGY LIMITED specialized in the filling machine ,capping machine,labeling machine,sealing machine,wrapping machine,production line and other packaging machinery , ZONESUN with many years of experience and technical expertise. Our team consists of a group of highly skilled and experienced professionals who can provide customers with high-quality packaging machinery products and professional after-sales service. We can provide customized packaging machinery solutions according to the specific needs and requirements of our customers, in order to meet their different production needs. From machine design, manufacturing, to after-sales service, we always put customer needs at the center and constantly improve the quality of our products and services, in order to provide customers with a better product and service experience. If you have any packaging machinery needs, please feel free to contact us at any time. We will be dedicated to serving you!

https://www.zonesunpack.com

E-mail:info@zonesunpack.com

Whatsapp:+0086 18924567106