Working Principles

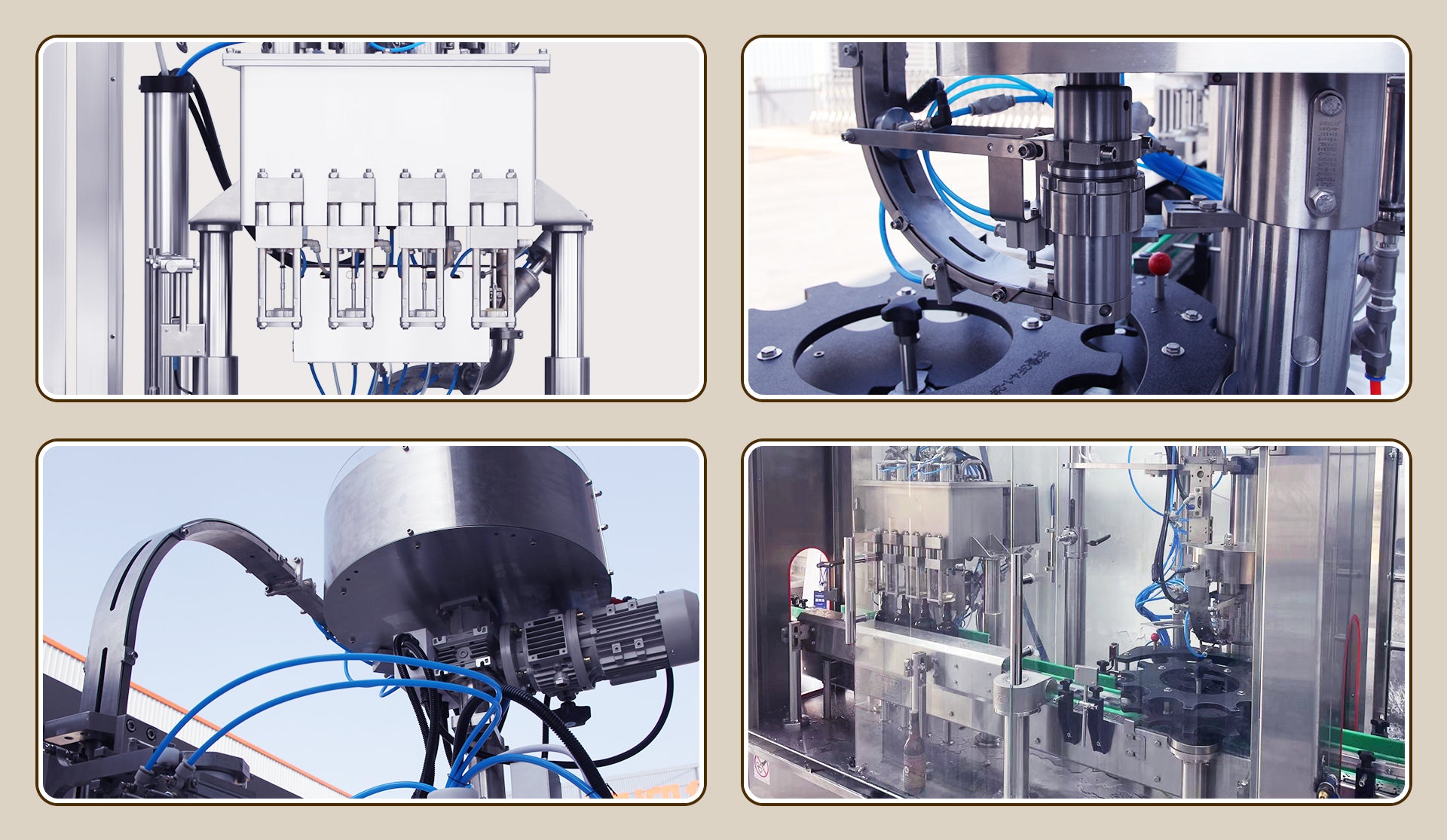

The automatic beer bottle filling and capping machine achieve highly automated filling and capping processes through advanced mechanical and electrical control systems. Its working principles mainly involve the following key steps:

- Bottle Feeding: Bottles enter the machine's working area through a conveyor belt or transfer system.

- Bottle Positioning: Sensors or mechanical devices precisely position the bottles in the correct position for subsequent filling and capping operations.

- Filling: An automatic measuring system accurately injects the predetermined volume of beer into each bottle, ensuring product consistency and accuracy.

- Capping: The capping head automatically places metal caps on the bottle necks and applies appropriate pressure to ensure a tight seal.

- Bottle Discharge: Bottles that have completed the filling and capping process smoothly exit the machine through a conveyor belt or transfer system, entering the next production phase.

Advantages

Compared to traditional manual operations, the automatic beer bottle filling and capping machine offer significant advantages:

- Increased Production Efficiency: The automated operation streamlines the filling and capping processes, greatly improving production capacity and reducing labor costs.

- Guaranteed Product Quality: Precise measuring systems and stable capping force ensure the beer is properly filled and the bottle caps tightly sealed, guaranteeing product quality and consistency.

- Enhanced Sanitary Safety: Automation reduces human interference, lowers the risk of external contamination, and ensures product hygiene and safety.

- Improved Flexibility: The automatic beer bottle filling and capping machine can accommodate bottles of different sizes and specifications, providing flexible production capacity and adaptability.

Positive Impacts

The application of automatic beer bottle filling and capping machines has positively impacted the brewing industry:

- Enhanced Competitiveness: Efficient production capacity and consistent product quality enable breweries to better meet market demand, thereby improving competitiveness.

- Cost Reduction: Automation reduces labor costs and the risk of human errors, resulting in lower production costs.

- Resource Conservation: The automatic beer bottle filling and capping machine precisely controls the amount of beer used, avoiding waste and reducing resource consumption.

- Enhanced Brand Image: Modern consumers are increasingly concerned about product quality and hygiene. The application of automatic beer bottle filling and capping machines provides more reliable product quality, enhancing brand image.

ZONESUN TECHNOLOGY LIMITED specialized in the filling machine ,capping machine,labeling machine,sealing machine,wrapping machine,production line and other packaging machinery , ZONESUN with many years of experience and technical expertise. Our team consists of a group of highly skilled and experienced professionals who can provide customers with high-quality packaging machinery products and professional after-sales service. We can provide customized packaging machinery solutions according to the specific needs and requirements of our customers, in order to meet their different production needs. From machine design, manufacturing, to after-sales service, we always put customer needs at the center and constantly improve the quality of our products and services, in order to provide customers with a better product and service experience. If you have any packaging machinery needs, please feel free to contact us at any time. We will be dedicated to serving you!

https://www.zonesunpack.com

E-mail:info@zonesunpack.com

Whatsapp:+0086 18924567106